A custom glass bottle is very exclusive to a specific brand. Developing custom glass bottles is a strategic marketing purpose to establish sustainable relationship with consumers. Creating personalized glass bottle is to make unique shaped bottles with special branded elements. Many brand owners prefer custom designed glass bottles to achieve brand loyalty and promote brand’s differentiation and recognition.

Custom made bottles are greatly demanded by high-end products especially liquor, vodka, whisky, premium wine and spirits, water, oils, custom glass beverage bottles, cosmetic and perfume industries. Personalized glass bottle is the most strong tool to convey brand’s personality and identity.

Why to develop custom glass bottles?

For brand owners, they choose the glass container packaging to protect liquid safe. What’s more, they want to ensure their product packaging attractive and outstanding on the shelf space. Wholesale glass bottles are common for packaging industries, and each brand owner can use the existing glass containers for product packaging.

Obviously, customized bottles are unique in shapes, sizes, colors or even special closure tops. To choose a custom glass bottle is to make your product special appearance, achieve a unique look and larger brand’s benefits.

1- Customised glass bottles will bring your designed glass bottles into quality commercial glass products.

2- Custom model will interact with your brand designs, presenting your product well and help you to gain repeated consumers.

3- Custom glass bottles are personalized bottle designs of innovation and creation, and new glass packaging ideas to differ from packaging containers from competitors on the shelf.

4- Customer-oriented marketing strategy is the first rule for product packaging design. Owning an appealing custom glass bottle, your product will get special attention from consumers.

How to create a custom glass bottle for a specific brand?

Develop custom glass bottles creatively is completed, time and money cost. Custom designed glass bottles request imagination, innovation, creation, uniqueness, good-function, perfect performance with specific product, and enough market research.

Custom glass bottle design works as the signature and DNA of the brand, for customized bottle making a product speak, reinforcing the brand message and giving the consumer additional information.

Step 1. Fnalize a custom bottle design

To create a custom glass bottle, the first thing is to appear up your unique designs for customized glass bottles. Some brand owners have different initial bottle designs, so our customization specialists will collect all the original bottle drawings and validate the feasibility of the custom bottle project.

As custom glass bottle manufacturer, our specialized designing team will consider the all aspects of custom designed bottles like function, aesthetics, feasibility.

Step 2: Technical bottle drawing

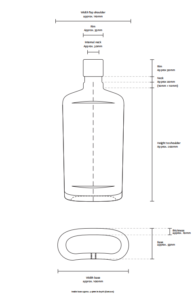

Making a custom glass bottle, the brand owner have various bottle options to create the new and market-trend personalized glass bottle. For example, the bottle shape, the capacity, the embossed logo, debossed logo, punt bottom, bottle weight. Once confirmed the bottle design, you can hire a professional designer to make 2D, 3D bottle technical drawing. No bottle drawing? Trust our designing team, they will make the technical drawing in AI, CDR, PDF format for brand owner’s approval.

Step 3. Custom glass bottle mold

High quality mold is the key to manufacture satisfied custom glass bottle production.Qualified bottle mold will ensure the mold durability and give a better bottle appearance. As expert bespoke bottle maker, the mold factory will study the custom bottle drawing and confirm the correct mold material, and give suggestions for high-quality glass bottle production.

For example, custom glass beverage bottles request normal casting mold bottom, while crystal flint glass bottles for liquor, premium wine and spirits request copper alloy mold material. That is why glass bottle molds for liquor and spirits are more expensive.

Step 4. Sample production for custom designed bottles

Customers are willing to test the physical custom bottle samples before bulk custom made bottle manufacturing process. Therefore, experienced custom bottle makers will provide custom designed bottle samples and post out sample for approval. Custom bottle mold is normally same as mass production for customized bottle.

Step 5. Mass production for the custom glass bottle

With the custom bottle samples’ approval, the next step is to arrange custom glass bottle manufacturing process. During glass bottle production, quality inspection is critical to exceed client’s expectation.

To ensure high-end custom glass bottles, the experienced bespoke glass bottle factory is operated under strict quality system. Apart from the automatic and semi-automatic inspection facilities, our professional quality inspectors and engineers check every glass bottle and jar to eliminate defected glass product.

Step 7. Safe packaging and saving-money logistics

Glass bottle containers are environmental and healthy, but glass products are fragile. Thus, safe and strong packaging for custom glass bottles will reduce damage. Ocean or marine shipping is the best delivery method for quantity glass bottles. Finding a reliable global logistic partner will be responsible for your custom-made bottles economically.

Benefits of a custom glass bottle

Developing a custom glass bottle means to creating a tailored bottle design that will look like no other yet is recognizable and identifies you. Each brand owns its unique story, its own value and its specific position, customizing a personalized glass packaging is a great tool to present your brand’s personality.

1- Proprietary

A custom made bottle provides a distinctive iconic look for your brand logo or brand name design. Custom bottles allow to create a unique shape and add your branding into the actual glass and provide a visual icon, for instance, embossed logo designs.

2- Anti-counterfeiting

Manufacturing custom glass bottles is a powerful way to protect your special brand design, effectively increasing anti-counterfeiting. Unlike wholesale glass bottles, the high cost of custom bottle’s development, difficulty in replication and hurdles in inventory provide strong barriers to counterfeiters.

3- Customization

Customized glass bottle allows the opportunity to create a special bottle that can highlight your product. Developing custom glass bottles, brand owners have options in unique bottle shape, size, color, weight, and closure caps.

Basic costs for creating a custom bottle manufacturing

Custom glass bottles are appealing to consumers, however, there are extra costs for manufacturing custom glass bottles. It is better to learn some basic fees for glass bottle customizing before starting your custom glass bottle projects.

1- Custom mold cost.

Glass bottles and jars are manufactured from a bottle mold, which has two parts. Every glass bottle shape and size even the bottle neck-finish requires a molding unit. Thus, the budget for custom designed bottles is different from existing glass containers. You should take the custom model cost into consideration.

Molding costs are different depending on the bottle design, weight, quantity and others. For example, custom 750ml glass liquor bottles mold cost usually start from USD2900.

Flint clear glass containers, custom mold costs id around USD1500 to USD2900. While for green and amber glass, the mold cost is more expensive, around USD11000.

2- Custom bottle samples cost.

Apart from the bespoke mold fee, there will be sample setup cost roughly USD800. Many brand owners require physical samples to test quality before mass production of custom glass bottles.

3- Inventory budget.

Unlike wholesale glass bottles, customized bottles will tie up your capital. There is the minimum quantity for creating a custom glass bottle, which request brand owner to prepare enough budget.

What is the MOQ to develop custom designed bottles?

For crystal, premium super flint glass bottles including liquor, spirits, our glass bottle factory can accept the MOQ 12000pcs for custom glass bottle production.

For flint glass bottle container like bottle for juice, beverages, milk, water, the MOQ is 50000pcs for custom bottle under size 250ml. MOQ 30000pcs for custom made bottles 500ml and larger. For big size customized bottle, the MOQ is 20,000pcs

For colored glass bottles including green and amber glass, the MOQ is 200,000pcs.

How to find expert custom glass bottle manufacturers

To create a new glass bottle design, it is crucial to find reliable custom glass bottle manufacturers. Custom glass bottles have unique look and design visually, but also customized bottles are tailored to convey branded printing and labeling.

For brand owners, you can search the Internet to find your best custom glass bottle supplier. Checking experience, custom bottle projects, manufacturing facilities, customization capability and after-sale service of the specialized factory.

Also, consulting with your friends who have made custom glass bottles, and contact their cooperated custom glass bottle makers.

Conclusion:

Personalization plays a more and more important role for packaging design. Every business owner desires a good look packaging to present the brand’s difference and personality. Customizing glass bottle packaging ensure your product seize consumer’s special attention.

Seekbottles, as a specialized glass bottle factory, has been expertise in custom glass bottle manufacturing for many years, and provided various individual glass containers creatively for worldwide clients. This glass bottle manufacturer has never stop to developing their imagination and innovation to help businesses to get quality customized bottles.

Looking for the best custom glass bottle manufacturer for your personalized bottle designing, manufacturing, decorating? We are at service to save money, save energy and save time!