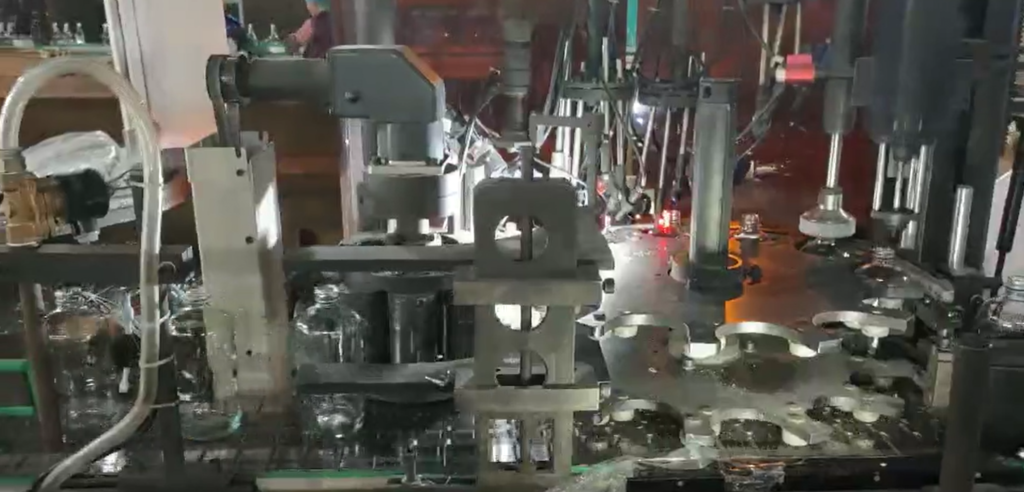

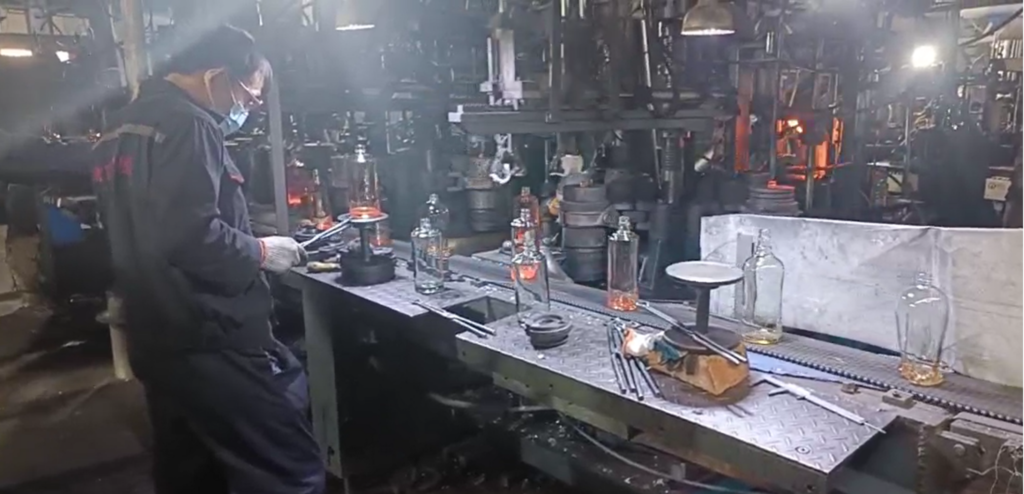

Standard glass bottles and jars are widely used in the market by any bottling company, no extra mould cost, and standard bottles are stocked continuously at consistent quality bulk for sale at wholesale prices and fast delivery.

Custom glass bottles are exclusively for one customer, bespoke bottle design for a specific product packaging. Brand owners especially premium wine and spirit, liquor, oil, water, cosmetics prefer customized glass bottles. Embossing, debossing, engraving and avaiable with custom models. For custom designed bottle production, there will be extra cost for bespoke molds, and minimum quantity from 10,000 to 300,000 depending on bottle sizes, colors etc.