Glass bottles and jars are very popular for all industries in our daily lif, for glass packaging is health, safe, reuseable, recycable, environment-friendly, sustainable. They are beautiful appearance, elegant feeling, suitable with various surface decorations. What’s more, glass packaging is deverse in shapes, colors, capacities, as well as cap closures, matching your requests for different products.

We are experienced China glass bottle manufacturer, supplier and wholesale, providing quality glass bottles and jars at factory prices. Self-owned glass bottle factory in China, making your glass packaging fast delivery. If you are in search of professional custom glass bottle manufactures, we are your best partner in longterm.

Process To Make Glass Bottles

Quality glass bottle manufacturing will provide you with glass containers that are very attractive and very safe to hold your products. Here following steps involved in glass bottle production. If you are interested in knowing how glass is made, please keep reading.

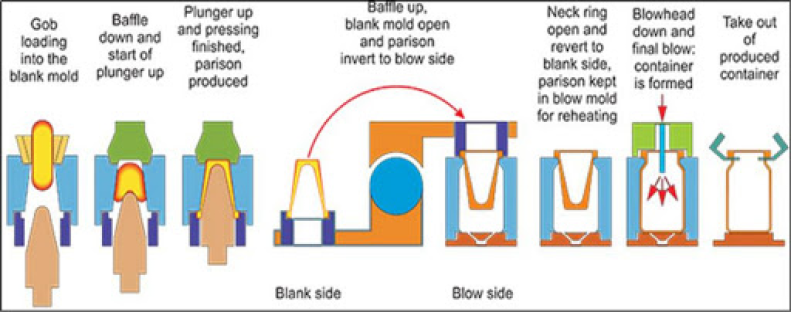

Manufacturing Steps

- Loading gobs of molten glass into molds through a very careful funnel process

- The baffle then begins the settle blow process to allow compressed air into the mold, forming the neck and container finish

- A plunger then moves into the finish to tighten the glass against the mold in the counterblow process, forming the parison

- The mold opens and the neck ring holds the glass container to invert it for the blow mold step to prepare for the next step

- A reheat steps makes sure the parison temperature coincides with the internal glass temperature for smoothing and even distribution of the glass to prevent breakage

- A final blow is executed to evenly tighten the glass against the blow mold to finalize the shape

- The new glass bottle is removed from the mold and transferred to a cooling plate

- From the cooling plate the glass bottle is then moved via conveyor to be packed and prepared for delivery

Why Glass Packaging

Thanks for the development of our technology, we have various options of food packaging, like plastic, metal, glass, wood etc. Here we will focus on glass and plastic containers. Why choose a glass water bottle over plastic? Because glass allows you to sip colder and more pure-tasting water, looks sleek and elegant, and is thicker and sturdier than plastic. Glass is also better for the planet: made from all-natural, sustainable raw materials, glass is 100% recyclable and can be reused endlessly. Plus, glass is just as portable as plastic, so you can take your bottle virtually anywhere!

Reason 1: Perceived Quality Between Glass vs Plastic

Consumers perceive a difference of quality in glass vs plastic. A 2015 study found that participants believed food products packaged in glass had a higher level of pleasantness than the same product stored in plastic. As it tends to be more expensive, glass offers a premium experience in look, feel and weight that can be essential for luxury fruit juices, craft cold brew or other products that want to promote a sophisticated image for marketing.

On the other hand, glass breaks. Plastic offers durability and ease of use. It could be dangerous if you gave a child or baby a glass bottle that he/she could easily drop. Plastic tends to be less slippery than glass, and it can be molded into a variety of shapes and sizes such as a neck with ergonomic finger molds for better grip and easy handling.

Reason 2: Difference in Characteristics & Chemical Compatibility

Glass offers inertness and impermeability ideal for sensitive products in the pharmaceutical or personal care industries as well as liquids that store for long periods of time such as spirits and other alcoholic beverages. It is less permeable to CO2 and O2 than plastic, keeping fizzy products bubbly longer. Able to handle a wide range of temperatures, glass will not warp under pasteurization.

Plastic is versatile. It comes in many varieties like polyethylene terephthalate (PET), high density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP) and more. Each of these materials has its own chemical compatibility properties, temperature rating, impact resistance, etc. With so many options, it’s likely you can find a plastic container suited for your product and use.

Reason 3: Shipping Glass vs Plastic in Bulk

Shipping glass can become expensive fast. This is because glass is typically more fragile and heavier than plastic, leading to higher freight costs. A plastic 2 fl. oz bottle may weigh only .023 lbs. while its glass counterpart weighs .177 lbs. This seems like a small difference when comparing a single bottle. When ordering pallets in bulk though, it can add up to large figures that impact your profit margin. Even with extreme care in shipping, some glass bottles might break during handling.

Plastic, on the other hand, is lightweight and durable, making it much more suitable for transportation than glass. It requires less gas and oil than glass to transport, expending less energy and leaving a smaller carbon footprint. If you need to ship your container long distances, plastic stands as the economic and often eco-friendly option.

Reason 4: Costs Comparision Between Glass & Plastic?

Not only is glass more expensive to ship, it also costs more to produce primarily due to the amount of heat required during production. Glass manufacturing is energy-intensive accounting for 1% of total industrial energy use in an Energy Information Administration (EIA) survey of the manufacturing sector. Natural gas fuels most of this energy.

The melting point of plastic is much lower than glass, requiring less energy during production. With new technology developments in plastic molding, manufacturing plastic containers has become even more affordable. At one point, producing new plastic was even cheaper than recycling it. Economically plastic exceeds glass in terms of both production and shipping.

Reason 5: Environmental Factors & Recycling

Although glass may take more energy to produce and ship, it is 100% recyclable meaning that each time glass is recycled, the resulting product has no loss of quality. Glass can also be reused as it can be washed and sterilized. Most plastic can be recycled, but it can degrade each cycle. This means that when you recycle a plastic bottle, it typically is not used to make another bottle and instead is used for synthetic clothing or carpets. This process is often called “downcycling.”

The environmental effects of glass and plastic are not clear cut. Glass makes up 5% of the garbage in the U.S, meaning that even though it is recyclable it often finds its way to the landfill anyway. Producing a single-use glass vs plastic container has a larger environmental impact due to the energy required. However, even though glass is long-lasting it is made from natural material. While plastic is relatively new compared to glass, plastic makes up 20% of garbage in landfills.

Reason 6: Impact to My Health

Glass is non-toxic, free from potentially harmful chemicals and generally not associated with a negative impact to your health. It is less porous than plastic. It also has a high resistance to leaching into your product even when contained for long periods of time. Organic or all-natural products may want to consider glass products as public knowledge increases of bisphenol A (BPA) and other potentially hazardous chemicals in plastics.

However, most plastics do not contain BPA. Plastic gets a bad reputation for its toxicity and tendency to leech into products. When used incorrectly, plastics can leech possibly harmful chemicals into your product. Improper or extreme storage conditions can accelerate this process. Taking precautions to ensure that your plastic container suits your product and its use can ensure that using plastic is a safe alternative to glass.

Reason 6: Wha’s Going Inside & How Will It Be Used

A large determining factor between glass and plastic is what works best for your product. If it’s a spirited beverage or a liquid where keeping carbonation is essential, glass might work best for you. Thick substances such as shampoos and lotions often fit a plastic bottle you can squeeze to dispense. Glass vs plastic might help your all-natural beverage sell better, but a product that a child or baby handles might be ideal in plastic.

How to Make Your Glass Bottle Unique, Attractive

If it takes 7 seconds to form a first impression of a stranger, it takes a fraction of that for a consumer to evaluate your product among others on the shelf. Unique screen silk printings, decoration printings or labels plays a large role in this. This will make your products special, attractive to customers. We have to admit that customers are visual, and they buy products maybe just because of the attactive packaging.

We offer various decorations for your glass bottles and jars, making your glass packaging unique appearance, boosting your brand value.

- Silkscreen print

- Decal print for full colors design

- Metallic print, like gold foil, silver foil

- Custom color paint, including 360° spraying and gradient painting

- Frosting surface, giving mysterious feeling

- Labels