Custom Bottle Designs From Custom Glass Bottle Manufacturer

Developing innovative glass packaging is an design art. Taking advantages of custom glass bottles to set your product standing out from competitors. To create a custom designed glass bottle is to choose a tailored bottle that is unique and aesthetic appeal. At same time, a creative bottle design is recognizable and identifies your brand logo and brand name.

Each year, brand owners like most liquor distilleries, spirits, water, oil, cosmetics highly demand custom glass bottles manufacturing. With the increasing competitive packaging market, designing a differentiating attractive custom glass bottle for your product is important. It is strategic and crucial to develop customized glass bottles and custom glass jars.

Surrounding with a number of glass bottle manufacturers on the internet, it is necessary to find trusted glass bottle suppliers. However, it is not easy to search reliable custom glass bottle manufacturer offering custom bottle designs to promote branding. Looking for best glass bottle factory to develop an original bottle with highest quality? Seekbottles is customized glass bottle manufacturer and specialist in packaging customization. Work with our glass bottle design specialists, design your custom glass bottles to create the bottle designs of your dreams.

Why Custom Glass Bottle Packaging?

The packaging is the first thing a customer notice about your product. Customers will choose the product with attractive appealing appearance before they fully read your product itself. Thus, a unique packaging solution is one of the main key to seize more customers and boost company value. That’s why more and more brand owners prefer to create innovative glass bottle designs uniquely.

Packaging companies will consider custom glass bottles when they can’t find desired glass containers from wholesale glass bottles and jars. Designing a custom special bottle will bring your dreamed bottle design into commercial glass products.

Obviously, custom glass bottles and jars give your brand a more luxurious, elegant, valuable and top-quality look. Also, it will present your product well and gain more repeated consumers. Customized glass bottles speak about your company’s culture, values, and commitments. And all these factors make your bottle designs distinctive and protective way for your branding.

How To Create Custom Glass Bottles?

We are leading custom glass bottle manufacturers and specialists in customization and creating innovative packaging solution. Our glass factory designs and offers custom glass shapes to promote your brands. Whether you are craft liquor creator, a boutique wine maker, a special oil producer, soda water designer, a custom made bottle is the marketing strategy.

Creating a unique custom designed bottle is the perfect way to convey the quality and uniqueness of your product. Rely on our customization services and custom bottle manufacturing process, we create, design, produce custom special bottles from the custom bottle conception to real customized glass bottle products step by step.

Step 1: Communicate Your Bottle Ideas To Create Bottle Drawing

For brand owners who desire custom glass bottle designs, taking advantages of the market tendency is the key step for your custom bottle project successful. It is important to take the bottle size, bottle shape, closure style into consideration when you developing your art drawing. Also, some brand owners prefer glass with embossed logo or debossed logo to showcase their brand designs.

Forward your bottle ideas to professional bottle designers and glass bottle manufacturers, they will help you confirm which bottle design is feasible. Once the bottle idea is confirmed, custom glass bottle manufacturers can make the bottle technical drawing in AI, DWG OR CDR format.

Step 2: Develop 2D or 3D Bottle Drawing

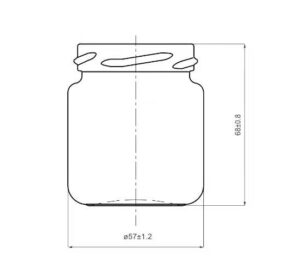

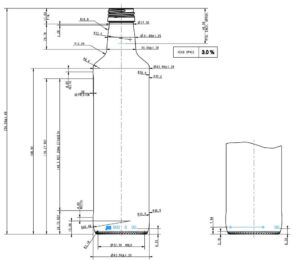

With the approval of technical drawing, our bottle designing team will give the 2D even 3D drawing based on detailed measurement, including bottle weight, height, diameter, neck-finish etc.

Step 3: Make The Molding

Developing correct and quality bottle mold is the key process for custom glass bottle manufacturing. Trust-worthy custom glass bottle manufacturers always have their own in-house mold factory and mold engineers. The main material for the mold is alloy steel castings, and some core part will be brass.

Different packaging industries have different requests for mold material. For example, commercial glass bottles and jars for food and beverages require standard molding. While extra flint glass bottles like liquor bottles, spirits bottles, luxury glass storage jars need premium quality mould materials.

Our mold factory will make the quality mold with proper material to ensure durable mass production, and offer custom glass bottles with a better appearance.

Step 4: Setup Sample Production

Are you worried about the custom glass bottle manufacturing or quality issues about your customized glass bottles? Setting physical bottle sample production is the perfect way to check the custom designed bottles. After making bottle mold, some brand owners require sample production to check quality and may have some modifications.

As a custom glass bottle maker, we do not suggest to order custom designed bottle samples unless you are plan to purchase quantity orders. Because sample production usually costs USD600-USD1000.

Step 5: Mass Production For Custom Designed Bottles

We produce and post sample bottles for client’s approval. Once confirm the sample bottles, your custom glass bottle will be under mass production as requested. Glass bottle manufacturing is operated with standard custom glass bottle process.

Thanks to 10 years experience in glass manufacturing industry, we are leading China glass bottle manufacturer today. Equipped with modern manufacturing machinery, well-trained employees, your innovative custom glass shaped bottles will exceed your glass expectation.

Step 6: Quality Inspection

Manufacturing custom glass bottles is never the last step for custom made bottle process. High quality is demanded for custom designed bottles, just as wholesale glass bottles manufacturing. We have our own strictly inspection system both automatically and manually. Our mission is to supply highest level glass bottle production and our goal is to supply best glass products to satisfy customers.

Step 7: Personalized Decorations Uniquely

For brand owners, a unique and attractive packaging will convey their brand value, communicate brand designs, brand logo and brand names with consumers. In order to achieve higher company value and boost brand market, decorated glass bottle with unique personalized customization will present the custom glass bottles in a better way.

Our glass bottle factory offers various affordable decorating and labeling for custom made bottles, for example printing, gold foil, frosting, painting, labeling etc. We are your one-stop solution packaging partner, supplying ready-to-use glass bottles and jars is one of our core competence.

FAQs About Custom Glass Bottles

Q 1: What is the minimum quantity for a custom glass bottle?

For normal flint glass bottle, the minimum quantity of a custom molded bottle starts from 20,000 to 50,000pcs depending on the bottle sizes.

For extra glass liquor bottles like vodka, whisky, gin, brandy, tequila, the minimum quantity of a custom bespoke bottle starts from 12,000 for 750m glass liquor bottles.

While for colored glass bottle like custom green bottle, amber bottle, the minimum quantity will be higher. For example, custom green wine bottle 750ml minimum quantity is 250,000pcs, custom green oil bottle minimum quantity is 200,000 to 300,000pcs

Q 2: What is the lead time for developing customized glass bottles?

Custom glass bottle manufacturing is different to wholesale glass bottles or existing glass packaging. From bottle design conception to mass production of custom shaped bottles, the lead time is around 12 weeks to 14 weeks. Therefore, customers should make the plan for custom designed bottle in advance before new product launching.

Q 3: How much is the molding cost for custom glass bottle manufacturing?

Developing a unique design and glass packaging with a real custom glass bottle manufacturer is significantly less expensive. For example, a set of mold cost offered by glass bottle manufacturers in Europe and glass bottle manufacturers in USA is around USD20,000 to USD30,000. This amount is much higher to some brand owners especially those small and medium packaging companies.

However, the mould with equal quality from China glass bottle manufacturer is only starting from USD1500 to USD12,000. Mold cost will depend on the custom glass bottle itself, like its color, its shape, its material, its capacity etc. If you want to know more about custom glass bottles and looking for trusted custom glass bottles manufacturers, contact us 24 hours 7 days freely to get quotes, get samples and bottle designs!

Conclusion

We are custom glass bottle manufacturers in China, offering custom glass bottle packaging creative and innovative custom designed packaging solution for brands. Forwarding your custom bottle designs and bottle ideas, we will be your side with every step. Our glass bottle factory will bring your dreamed customized glass bottles into real glass products. You pour your love to custom glass bottles, and we pour your custom glass bottle to quality custom-made bottles.